Small Tradeshow Budget and Booth, Big Impact: 4 Ways to Improve ROI

In the whirlwind of a large-scale trade show, a 10×10 booth can easily fade into the background. These compact booths often get overlooked and lost...

3 min read

Michele Nichols Thu, Aug 03, 2023

Automation and digital transformation are the next revolution in productivity. This is driven by a severe shortage of skilled labor and supply chain disruption is capping growth for advanced manufacturing across the sectors we serve. Automation has the potential to improve output, introduce new capabilities, improve margin, and grow revenue—but the skilled labor gap is making this change an imperative.

Automation is not about replacing jobs but maximizing output from available people and elevating their skills to remain competitive. Even for companies not looking for exponential growth, automation can help increase yield and improve margins.

Download the Digital Transformation Change Management Guide

US GDP growth is projected at 1.1% for 2023, downgraded due to this labor shortage. There is an anticipated 2M unfilled manufacturing jobs by 2025, and today, we have 35% more unfilled manufacturing jobs than skilled workers.

Leaders are turning to automation to address this gap.

Most of the business leaders in the industrial sectors we serve are undergoing digital transformation and the move to automation, taking on projects like:

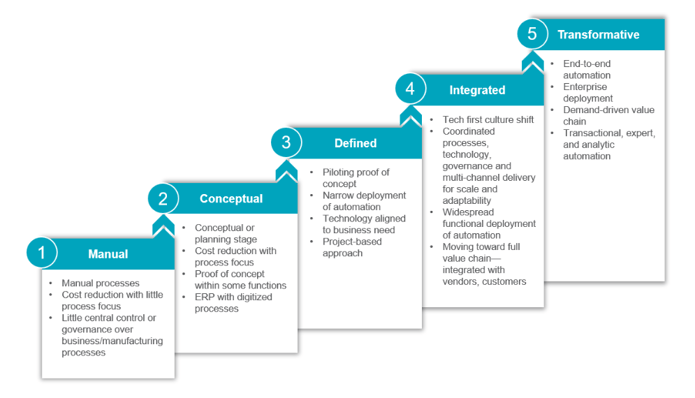

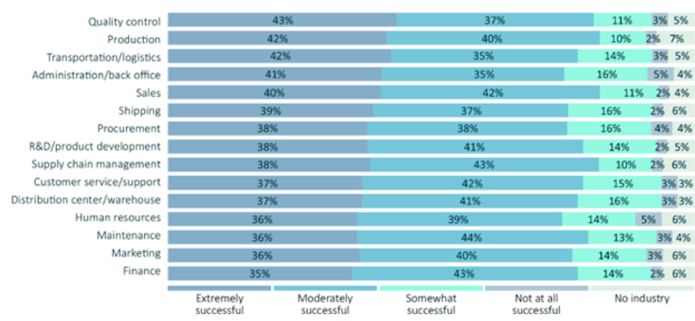

Moves like these are driven by a need to improve efficiency and productivity, reduce costs, improve safety, improve yield and quality, and enable data-driven decisions. Companies of all sizes have invested in automation, with most of these companies falling in “stage 3” of automation adoption—piloting proof of concept with narrow deployment. They are approaching automation as projects, moving toward a tech-first culture and widespread deployment.

The leaders we’ve spoken with, most of whom are in stage 3, have seen success in these projects, but their barriers to full automation are not uncommon:

“Too big a focus” is one of the misconceptions that hold the industry back. In fact, there’s no big reveal. Full, lights-out automation suffers from a perceived enormous investment, especially with interest rates on the rise, and that has stalled progress. But automation isn't an all-or-nothing shift. In fact, it’s continuous improvement that is paying off for the winners, with 20% gains as a rule of thumb at each step.

Credit: SaS Executive Briefing

An end-to-end, iterative approach presents its own challenges. To succeed, the move to automation demands a strong executive sponsor and widespread innovation. It’s a culture shift that demands change readiness.

Automation, even when broken down into manageable steps, demands change as it affects all layers of an organization. It’s a change that involves people, processes, and technology.

Here are a few ways companies manage change:

| People | Process | Technology |

|

|

|

Launch Team works with companies to set the vision and guide employees through the change required for digital transformation success. Learn more about our process.

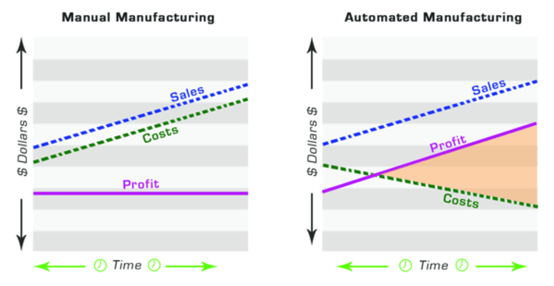

There is a measurable and compelling ROI to automation, but companies must take into consideration the cost of implementation and training. In a study of advanced manufacturing companies, the highest gains were reported in revenue, customer value, production capacity and quality, and most were able to demonstrate ROI in 18-24 months, though this varies widely based on the type of automation project.

Capital investment is one of the top barriers cited at every stage of automation maturity. And for good reason: interest rates are impacting margins, access to capital is changing, and privately held companies must consider their exit plan before major investment, while PE or VC-owned companies may need to see the business case for short-term ROI. The real payoff is in cash flow over time and new revenue opportunities.

Credit: Association for Advanced Automation

Automation and digital transformation may be the key to competitive advantage and sustainable profitability, but most advanced manufacturers are approaching it as an iterative journey, improving profitability and quality at every step.

ROI and benchmark data vary widely by type of automation and your specific operations, market, and geography. [Ask for a consult, and we’ll provide specific benchmarks where we can.] Here are some KPIs (key performance indicators) that may be helpful to baseline, benchmark, and track your progress:

Ready to speed adoption and results from automation and digital transformation? It requires a culture of innovation and continuous improvement to stay ahead of the curve. Launch Team has a strong track record of helping companies grow and change. Download our guide.

In the whirlwind of a large-scale trade show, a 10×10 booth can easily fade into the background. These compact booths often get overlooked and lost...

Featuring insights from Starlet Smith, Lead Agile Coach at Alliant Energy Product development cycles are lengthening, increasing the risk of missing...

We work with B2B leaders every day who have extensive marketing data, but don't know what to make of it. It's hard to know you're on track to meet...