Small Tradeshow Budget and Booth, Big Impact: 4 Ways to Improve ROI

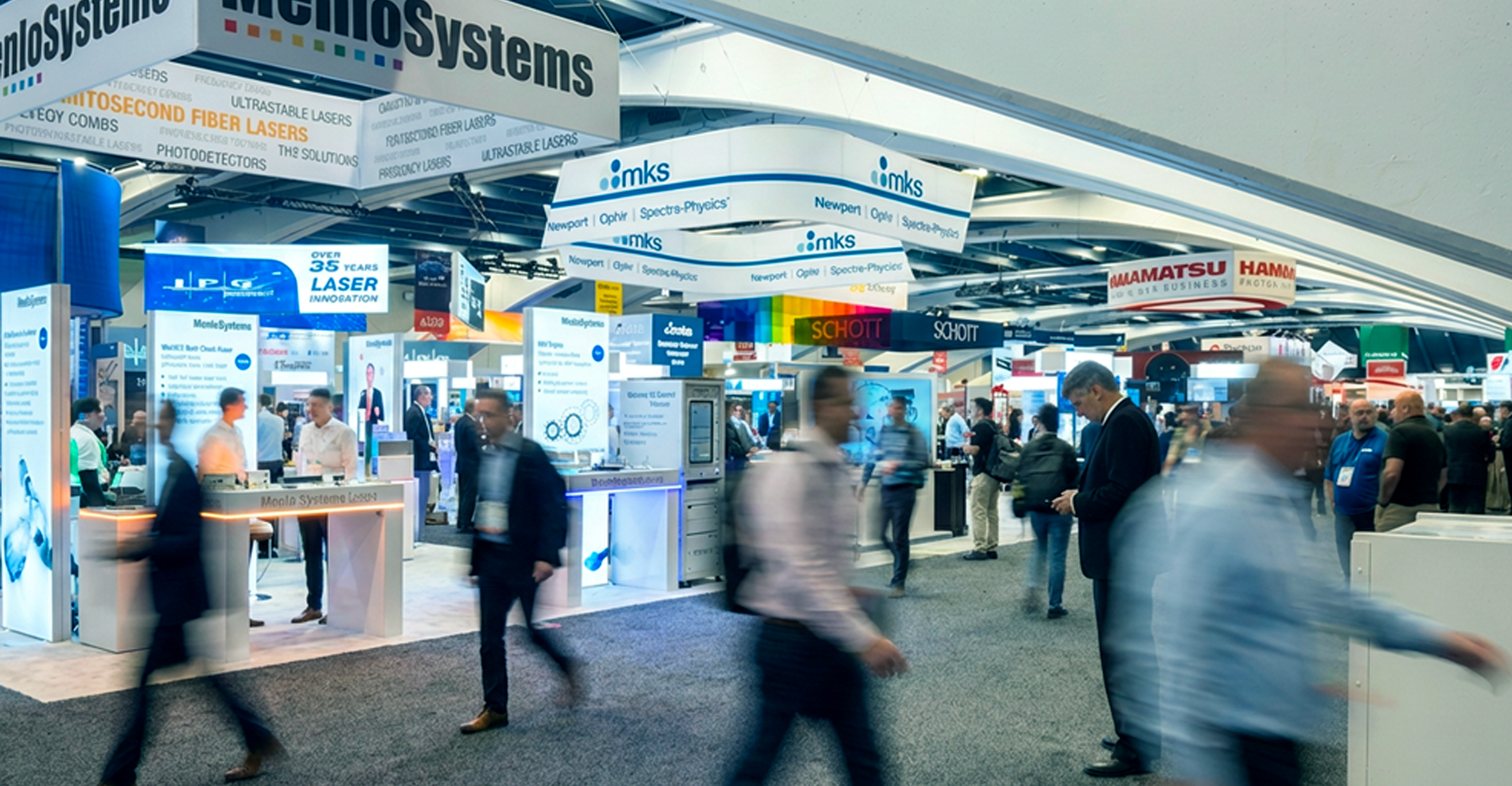

In the whirlwind of a large-scale trade show, a 10×10 booth can easily fade into the background. These compact booths often get overlooked and lost...

4 min read

Nate Fuller Tue, Jun 26, 2018

With the rapid advancements in head up display (HUD) technology in the automotive industry, the futuristic Hollywood depictions of holographic windshield screens are quickly becoming reality. Augmented reality (AR) windshield HUDs are becoming a large focus for mainstream automakers and suppliers to the point where it is expected that the market for HUD components market is expected to grow more than $5 billion in the next four years, becoming an $8 billion industry.

With the rapid advancements in head up display (HUD) technology in the automotive industry, the futuristic Hollywood depictions of holographic windshield screens are quickly becoming reality. Augmented reality (AR) windshield HUDs are becoming a large focus for mainstream automakers and suppliers to the point where it is expected that the market for HUD components market is expected to grow more than $5 billion in the next four years, becoming an $8 billion industry.

To learn more on the latest advancements and industry trends, I sat down with a Senior Hardware Design Engineer at a Tier-II firm, with previous engineering experience at a Tier-I firm. Their company focuses on the prototyping and early development of head up displays, partnering with automotive companies to move into production.

What are some of the most interesting aspects of working with HUDs?

The entire market is becoming very interesting as OEMs want a larger field of view, which means bigger HUDs. Advancements toward increasing field of view and shrinking package sizes are being made, but it has reached a point where current tech can only get so small. The industry is looking forward to tech developments that will allow them to go even smaller.

If you haven’t experienced HUD technology in a vehicle, I recommend test driving the new Lincoln Continental equipped with one of the largest field of view HUDs on the market. It uses the newer DLP projection method. The Cadillac XTS features the older TFT projection display, but it stills gives a great experience.

What are some of the biggest challenges you face working with HUDs?

When it comes to AR HUDs, latency is a major safety concern. When on the road, the vehicle’s sensors must recognize an object, send the signal to the computer, compute the outcome, and then alert the driver. All of this needs to happen in milliseconds. The amount of electronics and speed of communication in a car is expected to grow.

High speed Ethernet connections are being used more commonly for internal communication to achieve these extreme data transfer speeds. I heard an interesting anecdote when I started at my current company: with the addition of all these electronic components in vehicles today, the cost of the silicon in a vehicle’s components is worth more than the steel on the car's frame.

What do you see for this industry in the future?

Rapid growth and various advancements in the technology are happening in the HUD industry. We predict automotive manufacturers will respond to the demand for HUDs by implementing the lower cost TFT projection HUDs in lower-end vehicles and projection HUDs with more luxury and larger field of view in higher end vehicles. [Learn about keeping up with these changing customer demands in marketing and sales.]

Where do most engineers go to research challenges?

Let’s say a new circuit or chip is needed for a project I am working on:

How do engineers in your position typically learn about suppliers or vendors when looking for someone new to work with?

Once again, Google is their best friend, especially if the engineer is really lost on where and how to source a specific product/component. Usually, a supplier relationship will come from recommendations within the firm’s, network such as an electronics distributor. Generally, the engineer will check the reference on (you guessed it) Google and do an on-site visit before making any large purchases. During these on-site visits, they sometimes ask the tough questions to see if the supplier really has the knowledge and experience to get the job done right. If a product requires extreme precision and is sensitive to minor changes, the engineer will usually order samples from multiple suppliers to test their ability and compare quality.

What qualities do you find most important when you are selecting a new supplier or vendor?

There are two major factors when picking suppliers:

Proper communication is not only responding to emails promptly and picking up the phone, but it’s being on the same page and focusing on the task at hand. For example, our firm asked for a small volume of PCBs to be manufactured for a prototype we were working on. Rather than focusing on getting that job done efficiently, the manufacturer was only interested in landing the higher volume part of our firm’s business. This lack of focus can lead to lost clients and sales for manufacturers.

Are suppliers in the prototype stage typically used in further production stages or commercialization?

Generally supplier involvement depends on two attributes: value and quality.

Value:

In one example, two chip manufacturers offered comparable products, one at a high price point and one at a low. The higher price point came with free circuit testing and engineering support which was invaluable to the engineer and his firm, making the pricier vendor the better choice.

Quality:.

The importance of quality can differ depending on which stage of production the firm is in. In the prototyping stage, higher quality materials are usually a necessity because certain parts, like plastic housings, are not as important in production models as they are in the prototypes.

What steps can a vendor or supplier take in order to be considered when you are in the prototyping stage?

Communication, roadmaps, and timeline/process transparency. Suppliers should be easy to reach and clearly communicate their processes. In the past, I have had problems with supplier and customer timelines not syncing up due to a supplier stretching the truth on timelines or lack of communication. Roadmaps are an easy way to stay at the top of a firm’s mind as a supplier. If a firm isn’t looking to purchase right now, a roadmap can give them a sense of how early in the process they need to contact you if they decide to purchase in the future.

For help planning your next product launch, download our checklist to make sure you don’t miss a beat.

In the whirlwind of a large-scale trade show, a 10×10 booth can easily fade into the background. These compact booths often get overlooked and lost...

Featuring insights from Starlet Smith, Lead Agile Coach at Alliant Energy Product development cycles are lengthening, increasing the risk of missing...

We work with B2B leaders every day who have extensive marketing data, but don't know what to make of it. It's hard to know you're on track to meet...