Small Tradeshow Budget and Booth, Big Impact: 4 Ways to Improve ROI

In the whirlwind of a large-scale trade show, a 10×10 booth can easily fade into the background. These compact booths often get overlooked and lost...

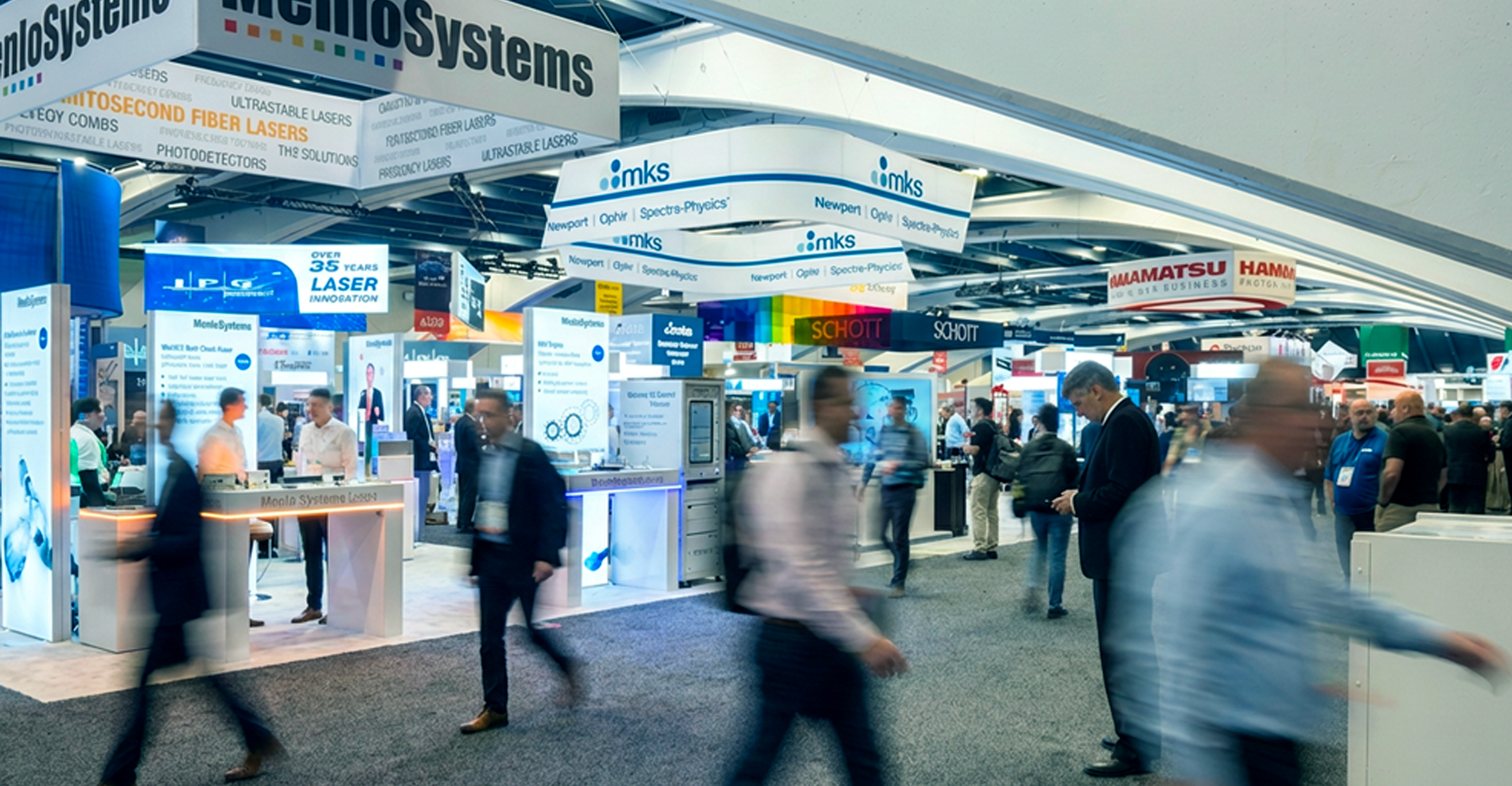

Returning from 2018 FABETCH, which spanned 3 exhibit halls and attracted over 30,000 attendees, we’ve had the opportunity to see and hear the concerns and market drivers US advanced manufacturers are facing. FABTECH was an excellent opportunity to take a step back from our work with advanced manufacturing clients throughout the US, for a broader, forward-thinking perspective.

Returning from 2018 FABETCH, which spanned 3 exhibit halls and attracted over 30,000 attendees, we’ve had the opportunity to see and hear the concerns and market drivers US advanced manufacturers are facing. FABTECH was an excellent opportunity to take a step back from our work with advanced manufacturing clients throughout the US, for a broader, forward-thinking perspective.

From the technology on display to the expert panels, it was clear: we’re in the middle of a revolution in manufacturing, driven by three technologies:

For some of our advanced manufacturing clients, additive manufacturing has already impacted their time to ramp up from sale to volume production, by reducing prototyping time. Long term, design capabilities represent a far more significant change: additive manufacturing allows for geometries that were not possible in the past, and is spurring significant investment in materials research.

There’s margin opportunity as well. The ability to manufacture as needed for end of life or replacement parts could improve customer satisfaction and profit margins.

Many of the early adopters of 3D printing have shifted their marketing message from technical capabilities to education on design and engineering possibilities. This content marketing is resulting in right-fit opportunities in which they offer a competitive advantage.

Check our more photos from the show here.

Companies like Vention, an exhibitor that describes the company as “legos for robots”, are working to reduce entry barriers with flexible, scalable components. Experts suggest that “robotics as a service” will become increasingly popular in North America for drones and other portable robots, as another means of reducing cost of entry in automation.

The move to the automated factory is far from simply an investment in capital equipment: it’s the organizational development, change in workforce needs, and rebranding and repositioning to target opportunities that best fit your new core competencies. While last year’s FABTECH shed light on the productivity valley—the gap between investment and productivity gains—2018 brings ready appetite for further automation, from robotic welding and cladding to robotic metrology.

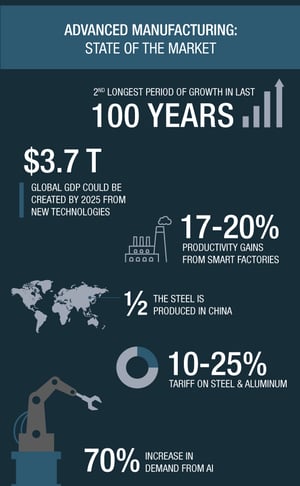

FABTECH panelist Michael Walton, Microsoft, is now seeing an average of 17-20% productivity gains from smart factories.

FABTECH panelist Michael Walton, Microsoft, is now seeing an average of 17-20% productivity gains from smart factories.

Matching demand to throughput remains a challenge, of course: Automation is certainly making its mark on sales and marketing as well. Data-driven systems to attract and anticipate the customers’ buying path are increasingly in use in advanced manufacturing for more accurate sales forecasts, and smooth, predictable pipelines.

27% of organizations have already incorporated some artificial intelligence into their key processes and services; and 46% have one or more AI pilots underway. What’s the payoff?

With changing capabilities and customer demands comes opportunity. Ready for a conversation about the changes you’re looking to make? Contact us.

If you're interested in learning more about the changing landscape and how it impacts your marketing and sales strategy, download the presentation slides.

In the whirlwind of a large-scale trade show, a 10×10 booth can easily fade into the background. These compact booths often get overlooked and lost...

Featuring insights from Starlet Smith, Lead Agile Coach at Alliant Energy Product development cycles are lengthening, increasing the risk of missing...

We work with B2B leaders every day who have extensive marketing data, but don't know what to make of it. It's hard to know you're on track to meet...